Greenhouse Gas Emissions Report

Steam and Chilled Water Tunnel Improvements

More than six miles of tunnel steam and chilled water distribution piping were assessed and repairs were made to leaking valve, steam traps and expansion joints. In addition, all missing or compromised piping insulation was replaced.

It is anticipated that these repairs will significantly reduce system losses attributable to piping transportation and thermal energy. This more efficient transportation system will reflect on the generation capacity required at the utility plants. The steam, and chilled water to a lesser degree, generation requirements will decrease, thus reducing University of Arizona greenhouse gas emissions. Decreased greenhouse gas emissions associated with the water mass flow loss will be garnered by the local Tucson water company.

Un-Islanding of 4.5 MW Turbine

The AHSC turbine, a 4.5 MW combined cycle unit, was previously islanded to specific equipment located within the refrigeration plant. This precluded the turbine from producing power and steam at full capacity. The turbine was recently un-islanded and now exports power to the campus electrical grid. This modification in operations allows the turbine to operate at full power and steam output.

With this change, a corresponding decrease in campus greenhouse gas emissions will result. The University's use of the natural gas turbine in lieu of the local electrical utility, which predominately utilizes coal based production units, is one more step towards reducing the campus carbon footprint.

Utilities Metering Upgrade Program

A comprehensive program has been instituted to measure all utilities and auxiliary equipment at the utility plants. This measure will enable Facilities Management to analyze its systems continually and respond to changes in data indicating possible maintenance issues.

All generating equipment (chillers and boilers) are measured for input and output. Additions to the metering system include the pumps and fans associated with production. Eventually, all utility plant make-up water and sewer system discharge will be metered.

Metering will allow the plant operators to determine plant efficiencies for steam and chilled water production and respond to changes real time. This measure will reduce greenhouse gas emissions by implementing changes immediately when problems are discovered.

High Efficiency Chillers and Boilers Installation

Several new chillers and boilers were installed at the utility plants. The new chillers are the most efficient on campus and will be used for base loading the existing chiller fleet. New boilers are modular, high efficient, condensing type, able to quickly respond to changing loads and thus mitigating the requirement for larger, less efficient boilers to maintain standby status.

These measures will reduce source energy requirements, both electrical and natural gas, helping to reduce the greenhouse gas emissions at the University of Arizona.

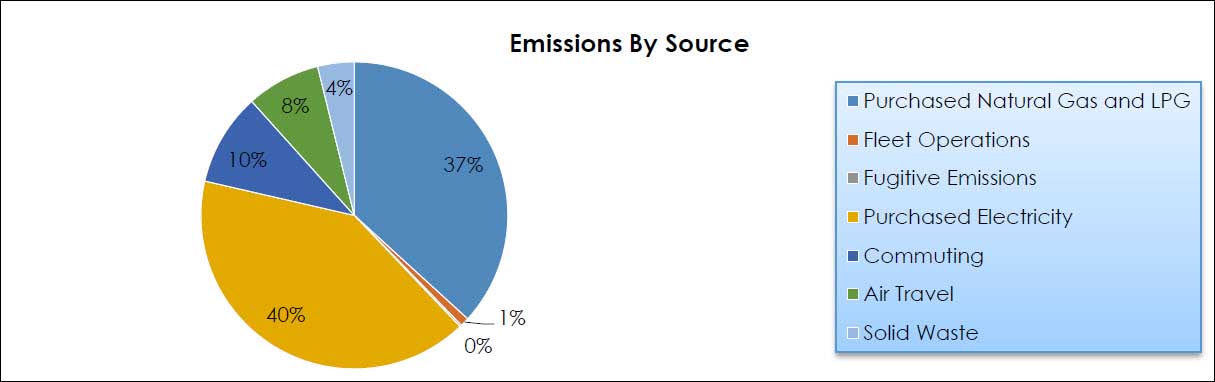

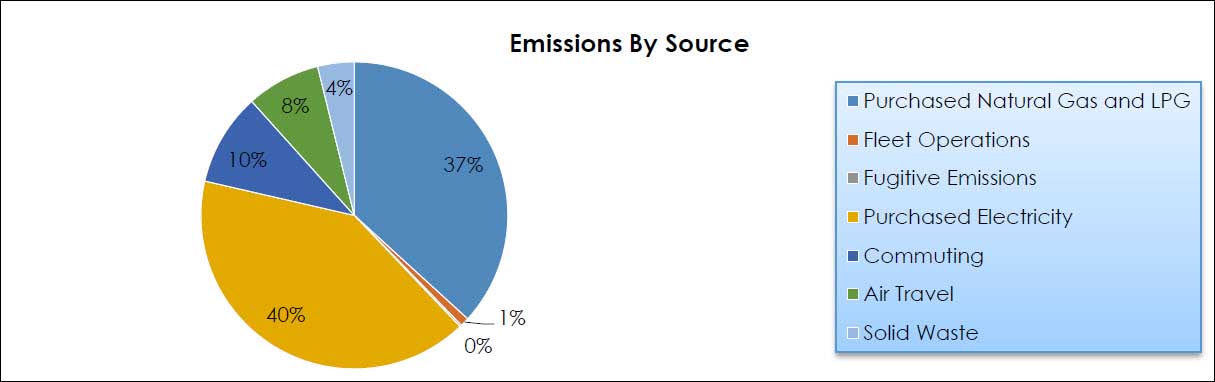

Emissions by Source